ElectroLips.com

TheWelcome to Electrolips.com, where innovation meets technology! At Electrolips, we specialize in delivering cutting-edge solutions that empower individuals and businesses alike. Dedicated to pushing the boundaries of what's possible, ensuring that our products and services stay ahead of the curve. We believe in harnessing the power of ambient conditions to employ technology and enhance everyday experiences, making life easier and more efficient for our customers. Explore our wide range of offerings.

Thank you for choosing Electrolips.com—your partner in technological advancement!

.

"The Earth itself operates as a massive gravity machine, utilizing crude oil for critical functions such as vibration dampening, thermal insulation, balance, structural support and tectonic lubrication. These natural processes contribute to plate stability, atmospheric integrity, and its role in sustaining life. As global industries push toward alternative energy sources, the transition must not disrupt fundamental planetary functions or economic systems globally, while ensuring scalability, sustainability, and commercial viability."Electrolips technologies has developed 19 versions of self propulsion power generation systems that we are attempting to switch the large energy companies over to without disruption of Global systems. For a cleaner tomorrow.

Electrolips LLC, headquartered in Berkeley, California, is a pioneering technology and energy innovation firm dedicated to developing advanced solutions across multiple sectors, including clean energy, aerodynamics, and ultraviolet (UV) sterilization. Founded by inventor John Pate, the company aims to harness ambient environmental forces to provide cleaner, more reliable, and efficient power solutions, thereby redefining energy independence and contributing to a brighter future

Core Innovations and Patent-Pending Technologies investing in electrolips hepls fund developement of:

Electrolips LLC's portfolio encompasses a range of patent bearing technologies designed to address contemporary challenges in energy, aerospace, and public health. Key innovations include:

Self-Sustaining Power Generation Units: Compact devices, approximately the size of a large commercial microwave, capable of powering an entire two-bedroom apartment. These units are engineered to generate more energy than they consume, offering a decentralized power solution ideal for both developed and developing regions. The independent energy systems existing interconnected through the grid will enable security and protection from brown outs, blackouts, harsh weather conditions destroying power from central stations to cities, towns and villages. One of the only downsides of this product is outcroppings bursting with people and creating more environmental damage.

Tidal and Riverbed Power Generation Systems: These systems exploit small water currents and natural flow dynamics to produce consistent energy, providing sustainable power in country towns and villages where the local utility comapny can employ green devices as these to power advanced electric dependent societies by utilizing small streams and rivers as well as tidal systems in coastal regions.

Compact High-Efficiency Wind Turbines: Utilizing weight displacement physics, these turbines are designed to power multi-ton energy systems with minimal mechanical input, enhancing the viability of wind energy in diverse settings.

Advanced Liquid Circuitry Systems: These systems enable energy capture and conversion with unprecedented efficiency rates, contributing to the advancement of renewable energy technologies. The technologies incorporated and integrated are much cleaner and greener in comparison to common tesla based IC parts and circuitry.

Stabilization Technologies: Aimed at dirigibles and scientific balloons, these innovations enhance the stability and duration of airborne research platforms, facilitating extended atmospheric studies. The shapes desinged create ariwedge technology that abruptly stops balloons and dirigibles from disleveling in the wind or by other occrance. This technology was developed for mine detection systems for Laos and Vitenam to safely locate and mark mines and other objects after inventor John Pate viewed a story on the news about the US government still refusing to remove the devices and creating a burocratic money circus at the farmers expense. Since then Mr Pate has utilized the stability concept and adapted it to air ships designes with the look of 1984 form and design utilizing the same concepts as the original one piece cell shape for the detection systems. the dynamics then morphed over a two week period to larger air ships and floating launch platforms , casinos and military/research platforms.

Gravity-Defying Propulsion and Launch Platforms: Designed to reduce fuel consumption and atmospheric resistance, these platforms improve the efficiency of extraterrestrial payload launches, marking a significant leap in aerospace technology. By Elevating th elaunch of cargo and small passenger craft at higher altitude air ension and gravitational factors are reduced and less harmful fuel needs to be burned for launch of extra terrestrial craft and satellites.

Autonomous Safety Systems for Electric Vehicles: These systems enhance pedestrian safety by ensuring silent electric vehicles are detectable in pedestrian-heavy zones, addressing a critical aspect of urban transportation safety.

Minefield Detection and Hazardous Material Marking Technologies: These innovations aim to improve environmental and industrial safety protocols by providing advanced methods for detecting and marking hazardous areas.

Next-Generation UVC Sterilization Technology: This fully automated, solar-powered, and chemical-free system is designed to revolutionize hygiene standards across hospitals, transit systems, homes, offices, and public facilities. The technology has received a positive recommendation from the World Intellectual Property Organization (WIPO) in Geneva, with publication number WO/2024/241184, dated November 28, 2024.

electrolips.com

Ocean and Harbor Biofuel Filtration Systems: Aimed at preventing pollution at the industrial output stage, these systems contribute to the preservation of marine ecosystems by filtering harmful substances before they enter aquatic environments.

electrolips.com

Strategic Vision and Investment Opportunities

Electrolips LLC is committed to redefining global standards in energy, aerospace, and industrial safety through high-margin, scalable solutions. The company seeks strategic partnerships across government, defense, transportation, and research sectors to accelerate the transition from patent to market. By securing early-stage capital, Electrolips aims to expedite its expansion and establish itself as a leader in clean technology innovation.

electrolips.com

Investors are presented with opportunities to engage in a diversified, high-growth clean-tech portfolio with exclusive early-stage equity and patent ownership rights. The company's business model is structured to offer significant returns on investment through licensing agreements and direct commercial sales. Electrolips LLC invites angel investors, venture capital firms, and private equity groups to collaborate in scaling next-generation energy solutions with disruptive, real-world applications.

electrolips.com

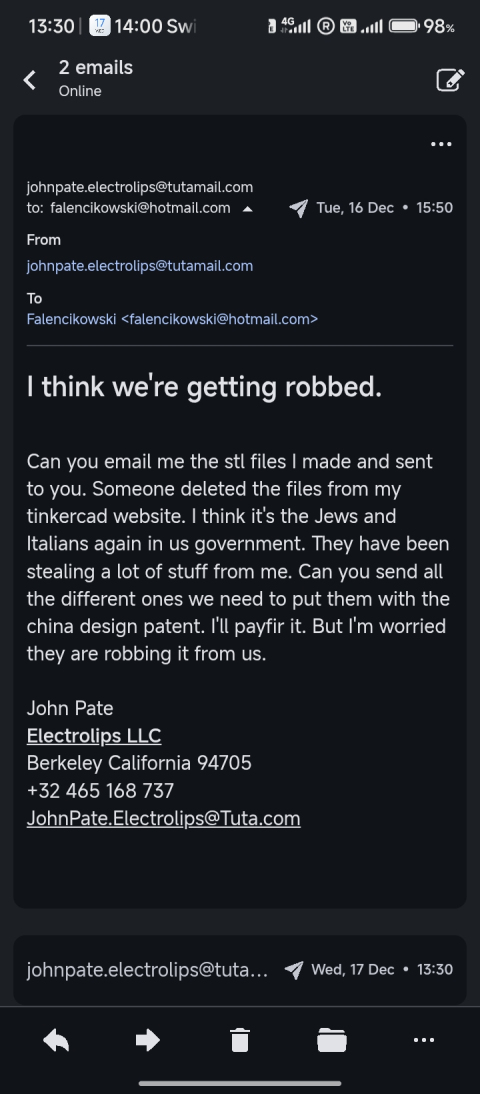

For more information and to explore investment opportunities, interested parties are encouraged to contact Electrolips LLC johnpate.electrolips@tutamail.com

electrolips.com

Transformative Clean Energy & Advanced Technology Investment Opportunity

Electrolips LLC – Innovations in Energy, Aerodynamics & UVC Sterilization

Introduction: The Earth's Natural Energy Dynamics & The Need for Disruptive Innovation.

The Earth itself operates as a massive gravity machine, utilizing crude oil for critical functions such as vibration dampening, thermal insulation, balance, structural support and tectonic lubrication. These natural processes contribute to plate stability, atmospheric integrity, and even gravity's role in sustaining life. As global industries push toward alternative energy sources, the transition must not disrupt fundamental planetary functions while ensuring scalability, sustainability, and commercial viability.

At Electrolips LLC, we are at the forefront of breakthrough energy technologies designed to harness ambient environmental forces—offering cleaner, more reliable, and more efficient power solutions. Our portfolio includes a suite of patent-pending technologies that generate more energy than they consume, redefining energy independence and aiding societies in undeveloped countries with decentralized power generation along with saving the consumer ontheir electricity bill here in first world developed countries.

Patent-Pending Technologies: Unlocking New Frontiers in Clean Energy & Aerospace

Non Disruptive Energy & Industrial Innovations

✅ Self-sustaining power generation units –

small-scale, high-output devices capable of powering an entire two-bedroom apartment

with a generator the size of a microwave.

✅ Tidal and riverbed power generation –

harnessing small water currents and natural flow dynamics to generate consistent, off-grid energy.

✅ Compact high-efficiency wind turbines –

leveraging weight displacement physics to power multi-ton energy systems with minimal mechanical input.

✅ Advanced piezoelectric fluid systems –

enabling energy capture and conversion at unprecedented efficiency rates.

Aerospace & Aerodynamic Breakthroughs

✅ High-altitude stabilization for dirigibles & scientific balloons –

redefining long-duration airborne research platforms.

✅ Gravity-defying propulsion & launch platforms –

reducing the fuel and atmospheric resistance required for extra-terrestrial payload launches.

✅ Electromagnetic catapult-assisted launch systems –

employing graphene and superheated noble gas technology for superior lift and thrust efficiency.

Safety & Sustainability Innovations

✅ Autonomous safety systems for electric vehicles –

ensuring silent-drive vehicle detection in pedestrian-heavy zones.

✅ Minefield detection & hazardous material marking –

enhancing environmental and industrial safety protocols.

✅ Next-gen UVC sterilization technology –

providing continuous and high-efficiency pathogen elimination for public spaces and healthcare facilities.

✅ Ocean & harbor biofuel filtration systems –

preventing pollution at the industrial output stage.

✅ Roof-mounted energy generation systems – r

etrofitting buses, trains, vessels, and aircraft with sustainable power solutions.

Strategic Vision: From Seed Investment

At Electrolips LLC, we don’t just create energy solutions—we redefine how energy, aerospace, and industrial safety function on a global scale. Our business model is structured for high-margin, high-impact scalability, with strategic partnerships across government, defense, transportation, and research sectors.

By securing early-stage capital, we will accelerate the patent-to-market pipeline and position Electrolips LLC for rapid expansion, acquisitions, and high-yield licensing agreements.

Investor Benefits & Next Steps

🔹 Exclusive early-stage equity & patent ownership rights

🔹 Access to a diversified, high-growth clean-tech portfolio

🔹 Strategic entry into trillion-dollar markets with first-mover advantage

🔹 Potential for significant ROI via licensing & direct commercial sales

We are currently engaging with angel investors, venture capital firms, and private equity groups interested in scaling next-generation energy solutions with disruptive, real-world applications.

If you are looking to be part of the clean energy revolution and position yourself at the forefront of the next industrial paradigm shift, let’s connect.

The future of energy, aerospace, and industrial innovation is here.

Will you be among the early visionaries investing in the future of energy independence and sustainable infrastructure?

CHECK OUT ARCHIVE.ORG and KEYWORD "ELECTROLIPS" or "ELECTROLIPSLLC" or "ELECTROLIPS LLC" or ELECTROLIPS.COM" or ELECTROLIPS.ONLINE" to see my full sites through the hacking the past couple of years! and remember the inventions these feds and team trump have been posting would all belong to me and the USA but he screwed Americans again like the tens of thousands of american contractors he did not pay for work completed on his lowlife construction projects. My inventions with my self propusion energy generators and piezoelectric fluid circuitry are worth hundreds of billions per year in revenue not counting the hundreds of othe rinventions stolen from me personally that the USA lost while you drained your accounts paying oil and electric bills over the past 20 years of financial fraud committed on me personally and financial crimes committed on me personally by my ex comembers of mar a lago and the Yugolavian colombo family (russians). never forget what a chump is trump. Federal illegally dismissed lawsuits for jihadist attack and coverup and hostage taking by the US federal government 9:24-cv-80327-amc judge aileen mercedes cannon march of 2024 illegally dismissed,

9:24-cv-80329-rlr judge reisenhart illegally dismissed march 2024 miami federal drug dealers- the clerk of courts would not enter an ajudication for me after the FBI refused to answer for over two weeks past the deadline and instead contacted the FBI and they dismissed the case illegally, the clerk of courts in miami needs to be imprissoned as well for refusal to submit my motion for adjudication after 3 weeks of the feds missing their deadline to respond and then contacting them to have them dismiss the case illegally on me. This is serious fraud by foreigners in the US government.

, Judge Tse norther district of california Pate vs Pate developement 3:21-cv-07718-agt illegally dismissed

Heading 1

Contact : JohnPate.electrolips@tutamail.com